DTF Vs Screen Printing: Which Is Better For Your Small Business Orders?

- Lindsay Miller

- Oct 8

- 5 min read

Choosing the right printing method for your small business can make or break your profit margins. If you're debating between DTF (Direct to Film) printing and screen printing, you're not alone, this decision stumps many small business owners who want to offer custom apparel without breaking the bank.

The short answer? For most small businesses, DTF printing is the clear winner when it comes to flexibility, startup costs, and handling the typical order sizes that small businesses receive. But let's dive deeper into why that is, and when screen printing might still make sense for your operation.

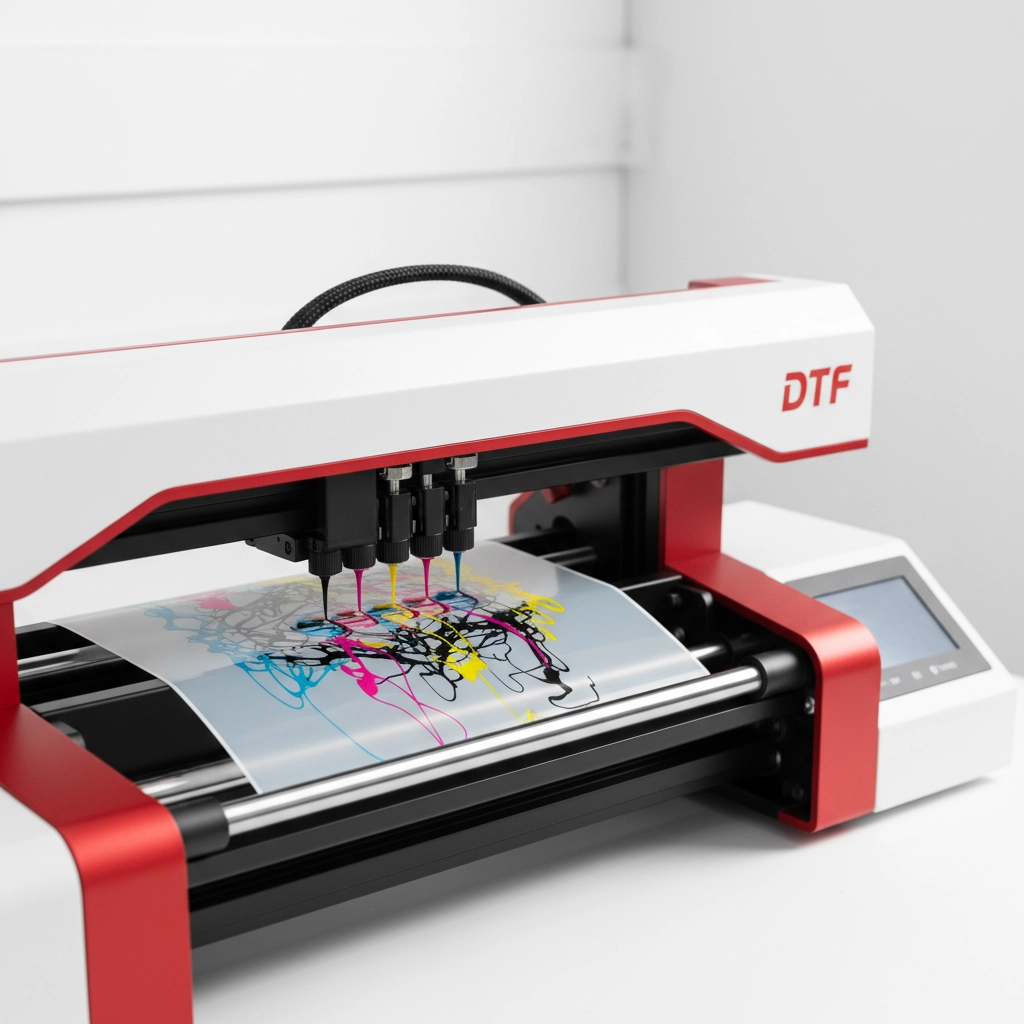

What Is DTF Printing?

Direct to Film printing is the new kid on the block that's been shaking up the custom apparel industry. Here's how it works: you print your design onto a special PET film using CMYK pigments and white ink, apply adhesive powder while the ink is still wet, then cure it with heat. Finally, you transfer the design to your garment using a heat press.

What makes DTF special is its simplicity. There's no screen creation, no color limitations, and no minimum order requirements. You can literally print one shirt as easily as you can print 100, making it perfect for small businesses that deal with custom orders or small batches.

What Is Screen Printing?

Screen printing has been around for decades and remains the go-to method for large-scale production. The process involves creating a stencil (or "screen") for each color in your design, then pushing ink through the mesh onto your fabric. Each color requires its own screen, which means more complex designs equal more setup time and cost.

Screen printing shines when you're doing big runs of the same design. Once those screens are made, you can pump out hundreds or thousands of pieces relatively quickly. But here's the catch, those upfront costs can be brutal for small orders.

The Cost Breakdown: Where Your Money Really Goes

Let's talk numbers, because that's what matters most for small businesses.

DTF Startup Costs:

Entry-level DTF printer: $1,500-$3,000

Heat press: $200-$500

Films, powders, and inks: $300-$500 initial stock

Total startup: $2,000-$4,000

Screen Printing Startup Costs:

Manual press setup: $500-$2,000

Screens, squeegees, inks: $500-$1,000

Washout booth and chemicals: $300-$800

Curing equipment: $200-$1,500

Total startup: $1,500-$5,300

While screen printing can have a lower entry point, here's where DTF really shines: per-order costs. With DTF, you pay roughly the same amount per piece whether you're printing 1 shirt or 50. With screen printing, you're paying those screen setup costs ($15-50 per color) on every single order, which can quickly eat into profits on small runs.

Order Size: The Make-or-Break Factor

This is where the rubber meets the road for small businesses. Most small operations aren't consistently getting orders for 500 identical t-shirts. You're probably dealing with:

Custom orders for 5-25 pieces

Event merchandise in smaller quantities

Personalized items with names or numbers

Sample runs for testing new designs

DTF printing handles all of these scenarios beautifully. No setup fees, no minimum quantities, and you can mix different designs in the same production run. Try doing that with screen printing and watch your costs skyrocket.

Screen printing becomes cost-effective around the 50-100 piece mark for simple designs, but most small businesses simply don't have consistent orders at that volume. Even when they do, they're often dealing with multiple designs or personalization requirements that make screen printing impractical.

Design Flexibility: Creativity vs. Simplicity

Here's where DTF printing really flexes its muscles. Want to print a full-color photograph? No problem. Complex gradients? Easy. Detailed artwork with 15 different colors? DTF doesn't care, it prints everything as one layer.

Screen printing works best with bold, simple designs using 1-4 colors max. Every additional color means another screen, more setup time, and higher costs. While skilled screen printers can achieve amazing results, they're working within constraints that DTF simply doesn't have.

For small businesses that want to offer truly custom, personalized products, DTF's design freedom is a game-changer. You can take any digital file and turn it into a high-quality transfer without worrying about color limitations or setup costs.

Speed and Turnaround Times

When a customer needs their order tomorrow, what printing method is going to save the day?

DTF printing follows a simple process: print, powder, cure, press. You can go from digital file to finished product in under 10 minutes for most items. There's no screen preparation, no ink mixing, and no complex setup procedures.

Screen printing requires creating screens for each color (which can take hours for new designs), setting up your press, mixing inks to match colors, and then running test prints before production begins. For a new design, you're looking at several hours of prep work before you even print your first piece.

Maintenance and Operational Considerations

DTF printers need regular use to prevent ink from drying in the lines, ideally daily operation or regular cleaning cycles. But the maintenance is mostly automated and doesn't require special skills.

Screen printing equipment can sit idle for months without issues, but when it's time to work, you need proper ventilation, chemical storage, and water systems for screen cleaning. There's also a learning curve that can take months to master.

For small businesses, DTF's "plug and play" operation is often more practical than screen printing's artisan requirements.

Material Compatibility: What Can You Print On?

Both methods work on cotton, polyester blends, and most standard apparel. DTF performs exceptionally well on dark fabrics and textured materials, while screen printing can expand beyond textiles to items like wood, metal, and plastic with specialized inks.

For most small businesses focused on apparel and fabric goods, DTF covers all the bases you'll need.

The Verdict: Making the Right Choice for Your Business

Choose DTF printing if you:

Handle orders under 50-100 pieces regularly

Want to offer personalized or custom designs

Work with complex, colorful artwork

Need quick turnaround times

Prefer lower upfront costs and predictable per-piece pricing

Want a simpler operation with less technical knowledge required

Consider screen printing if you:

Consistently receive bulk orders of 100+ identical pieces

Focus on simple, bold designs with few colors

Have the space, skills, and time for proper setup

Can afford higher upfront investments for lower per-unit costs on large runs

Plan to expand into non-textile products

For the vast majority of small businesses, DTF printing offers the best combination of flexibility, cost-effectiveness, and ease of operation. The ability to produce high-quality prints without minimum orders or complex setup makes it particularly well-suited for businesses that prioritize customer service and quick turnaround times.

Getting Started with the Right Equipment

Whether you choose DTF or screen printing, having the right partner makes all the difference. If you're ready to explore custom printing options for your business, or need help determining which method works best for your specific needs, contact us at Ink N Stitch. We can help you evaluate your options and get started with the printing method that makes the most sense for your business goals and budget.

The custom apparel market isn't slowing down, and small businesses that can offer high-quality, flexible printing services are positioned to capture a significant share of that growth. Choose the method that lets you say "yes" to more orders, and watch your business grow accordingly.

Comments